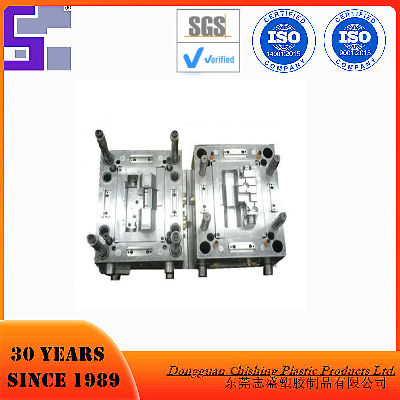

Plastic Injection MoldProduct Material ABS, PA, PA66+30GF,

PBT, PC, POM, PP, PE, MA,PVC,TPE,TPU etc Material of

Steel738,718,NAK80,S136,P20 etcSurface RequirementSmooth,

Polishing, Painting, SandBlasting, Electroplate, Silk-screen, Laser

Etching, Anodizing,BrushingTolerance Request UP

to (±0.005mm)Mould Life500000-1200000 shootsMulti

InjectionSingle/Double/multi colorDesign

SoftwarePro/E,UG,Catia,Woodwork,Moldflow,AutoCad Injection

SystemHot /Cold RunnerInserts(cavity and core) H13, 1.2344,

1.2738, 1.2083, 1.2311, NAK80 or the material you requiredMold

Cavity 1*1,1+1,1*2,1+1+1,etc Gate typeSide gate,Sub

gate,Pin point gate,Edge gate etcEjector SystemStripper

plate,Lifter,Push bar,Ejection pin etc Steel

StandardFINKL,Assab,DAIDO,LKM,Buderus CoolingBaffles/Sprin

Piple/3D printing water lineStandard

Parts/CylindersDME/HASCO/PROGRESSIVE/MISUMI/Parker/HP/MerkleDesign

CapabilityDFM,Mould flow analysis,Product optimization, Full 2D &

3D mould design,Reverse engineering,Collaborative design with

customer's ideaDocuments / Reports ProvidedFully drawing,Weekly

Processing Report, Steel Dimension report, Processing Report,Sample

Dimension ReportCertificateISO9001 ISO14001 MOQ1setsLead

Time6-10 weeks or according to the order

requirementPayment40%Deposit, 30%Before Product Inspection,

30%Before ShipmentPort of loadingSHUNDE/GUANGZHOU/SHENZHENOur

Staffs:Mould Trade Process: FAQ:Q: Are you a factory or

trading company?A: We are a professional manufacturer of injection

mold for above 30 years in Donguan China.Q: Can you do Assemble?A:

Of cause we could do. Our factory with assembly room.Q: I have an

idea for a new product, but not sure if it can be manufactured. Can

you help?A: Yes! We are always happy to work with potential

customers to evaluate the technical feasibility of your idea or

design and we can advise on materials, tooling and likely set-up

costs.Q: My products have already been developed on CAD. Can you

use the drawings?A: Yes! DWG, DXF, IGES, Solidworks and Rhino files

can all be used to generate quotes, models and mould tools - this

can save time and money in producing your parts.Q: Can I test my

idea/product before committing to mould tool manufacture?A: Sure,

we can use CAD drawings to make models and prototyping for design

and functional evaluations.Q: What shall we do if we do not have

drawings?A: Please send your sample to our factory,then we can copy

or provide you better solutions. Please send us pictures or drafts

with dimensions(Length,Hight,Width),CAD or 3D file will be made for

you if placed order.Q: What type of mould tool do I need?A: Mould

tools can be either single cavity (one part at a time) or

multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools

are generally used for small quantities, up to 10,000 parts per

year whereas multi-cavity tools are for larger quantities. We can

look at your projected annual requirements and recommend which

would be best for you.Q: How can we guarantee the quality?A:

24Hours online services,end to end design scheme;

Always a pre-3times test before package;

Always final Inspection before shipment;

Always provide technical support for all the time.Q: How long is

your delivery time?A: Generally 5-7 days for plastic products.25

days around to make a simple molds, complicated ones can be 30~50

days. We use our company DHL, TNT, UPS account to ensure the fast

product delivery time.Q: How many times try out?A: 3 times and

every time 2 sets sample with free delivery via DHL. Q: What

should we do if we receive defective products?A: Once receive

defective product, please send us the photos, we will feedback to

our engineers and QC departments and solve the problems ASAP

Q: What is your terms of payment ?A: Paypal, T/T. or

you want. Back to Home to Know MoreContact /* March 10,

2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Widely Used High Quality Antenna Plastic Panel Molding Making Plastic Injection Moulding Maker

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup