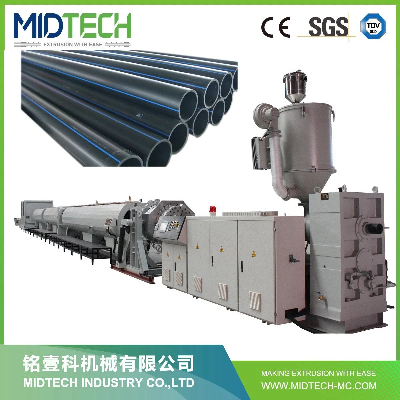

HDPE/PPR/LDPEplastic Pipe extrusion and production

lineWorkshop:PART 1 INTRODUCTION: Through

technology combination and continuous innovation,

Midtech pleased to provide energy saving (15%

down), high capacity (exceed 25% ), high standard (PLC

Intelligence), reliable quality (SKF bearing) PE/LDPE/PPR

Extruder and pipe extrusion and production line.

Pipe Diameter16-6332-12575-250110-450315-630315-800Extruder45/3365/3375/3390/33120/33150/33Cavitysingle strandsingle strandsingle strandsingle strandsingle strandsingle strandDownstreamLG63LG125LG250LG450LG630 LG800 Total power(kw)70150230380550800PART

2 Working flown of the pipe production line

Feeder• To feed material into extruder;Extruder• High

torque gearbox with adopts NSK/SKF bearing;• Siemens/WEG

original motor achieved global after service;• Up to 30m/min

of maximum lineal extrusion speed for small

pipes • Suitable for multi-layers co extrusion

from 1-5 layers;• Intelligent PLC controlling system

with operation-friendly interface. Die

head• PCA increased extrusion speed and decrease the

cooling length, quality inner wall surface;• The

Bronze bush is wear-resisting and efficiency cooling

of pipe surface.Calibration TankSpray tank• Big water

flown filtration system• Mechanical Water level and

temperature control systemHaul off• Variant 2-16

claws based on different pipe diameters,

• Equipped with servo control system for wide

diameter range.Cutter• Chip-free cutter

ensuing flat and smooth cutting surface of

pipe. Stacker• Discharge driving by air

cylinderWinder• Suitable for diameter from

5mm-110mmPART 3 Why choose usIf you do need any

support, please don't hesitate to contact us. /* March 10,

2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about HDPE Water Supply and Gas Supply Pipe Extrusion Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup