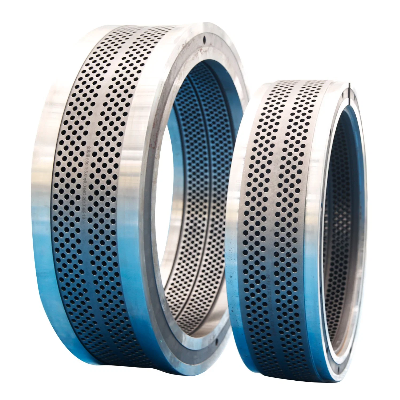

ApplicationRing die/Circular Mould is the key part of Ring Die

Pellet Mill in the large scale pellet plant to produce animal feed,

wood pellets, poultry feed,livestock feed,aqua feed, bio-mass

pellet and other granules.The quality of ring die plays an

important role in making high quality pellets and high output,also

can save much maintenance cost for pellet manufacturers.Feature of

our ring die:1Made of imported high-carbon high-chromium stainless

billet steel,optimization carbon,thus enhancing wearing and

corrosion resistance and hardness.2 It can deal with all kinds

of die hole over &1.2mm (&1.2mm included) and compression

ratio.3Ring die can be produced up to 300mm-1500mm in diameter

and 500mm in height.4In ring die processing, full automatic

control, one-time molding for die hole, high

smoothness. strong tensile strength,good wear resistance, good

corrosion resistance,high wear resistance,long life Advantage

of our ring die:1.Material refining technology,fewer

impurities,high purity,largely reducing harmful elements

content(such as elements S,P ), thus comprehensive mechanical

performance of material is raised.2.Through roll forging, material

is processed and strengthened and material fibre is complete and

uniform, which increases integrated mechanical performance of

material.3.Kingoro Company has the world advanced forging equipment

and technology,electronic data processing systems and perfect

quality control system.4.Ring die blank,generally chromiumalloy

roll forgings, some factories use 45 ordinary carbon

steel.5.Hardness of blank must be controlled, ranging from HB170 to

HB220.If the hardness is too high,the drill is easy to break

and happens with die hole when drilling. If hardness is too low,

the surface finish of die hole will be not good.6.In order to

control blank inner material uniformity, every blank must be

carried out with fault detection, which can avoid defects such

as flaw, pore-free,crackle and inclusions etc.7.After machining and

heat treatment process, hardness of ring die can be up to HRC

52-58(inner diameter less than 350mm),HRC50-56(inner diameter more

than 350mm),more wearable and anti-corrosion.8.In order to

control hardness uniformity of ring die after heat treatment, we

choose more than three points in each part of trisection of

peripheral direction to test hardness and take average.The

difference of hardness value between each part should not be

higher than HRC4.9.According to the principle of metal material

science combined with gas quenching and C,Cr,Mn,Ni,V elements

content is optimized, forming the standard of ring die.Introduction

of pellet machine ring die1. Material of the ring die: 46Cr13

/4Cr13(stainless steel)2. Hardness of ring

dies: 52-60 HRC3. Diameter of ring die can do: 1.0mm

up to 28mm4. Pellet die type can do: Ring Die or Flat Die5.

Outer diameter can do: Outer diameter up to 1800mm6. Pellet

Die model we can customizeOur companyShandong Kingoro Machinery was

established in 1995 and has 25 years of manufacturing experience.

Our company is located in beautiful Jinan, Shandong, China.We can

supply complete pellet machine production line for biomass

material, include chipping, milling, drying, pelletizing, cooling

and packing, according to different requirements of our customers.

We also offer industry risk evaluation and supply suitable solution

according to different workshop. Kingoro as

an advanced manufacturer of biomass pelletizers, owns 17 national

patents and has obtained IS09001 quality system certification, CE

certification, and SGS certification./* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Stainless Steel Ring Die Spare Part

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup