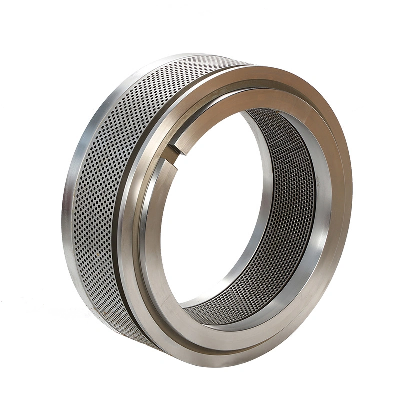

Product DescriptionX46CR13 VACCUM HEAT TREATMENT FEED MACHINE WOOD

PELLET MILL RING ROLLER DIE AS SPARE FORGING PARTS OF PELLET

MACHINE Our ring die is applicable for:1.Biomass pellet

machine: wood pellet mill, sawdust pellet mill, grass pellet mill,

straw pellet mill, crop stalk pellet machine, alfalfa pellet mill

etc.2.Fertilizer pellet machine, all kinds of

animal/poultry/livestock feed pellet machine. We can make many

famous models ring die & roller shells,such as:SZLH,CPM,

B.uhler, PTN, Andritz Sprout, Matador, Amandus Kahl, Muyang,

Paladin, Sogem, Van Arssen, Yemmak, Promill,etc.We make all kinds

of pellet mill ring dies according to customers' drawing. •

For Zhengchang pellet mill: SZLH250,

SZLH300,SZLH320,SZLH350,SZLH400,SZLH420,SZLH508, SZLH678, SZLH768,

etc• For Muyang pellet mill: MUZL180, MUZL350, MUZL420, MUZL600,

MUZL1200, MUZL610, MUZL1210, MUZL1610, MUZL2010;MUZL350X, MUZL420X,

MUZL600X, MUZL1200X(Especially for shrimp feed pellet, diameter:

1.2-2.5mm)• For Awalia pellet mill: Awalia 420, Awalia350, etc• For

B.uhler pellet mill: B.uhler304, B.uhler420, B.uhler520,

B.uhler660, B.uhler900, etc.• Other kinds. Product NameAlloy

steel forging ring die for pellet maker machineMaterialAlloy

steelColorNickel whiteStandardMeet the Industry standardGradeFirst

levelBradeRockThreadCoarse, fine Ring Die Product Show

Manufacturer Process and FacilityProcess for making ring dies /

flat dies spare parts, pellet diesBlank raw material

Forging---Rough turning---Half finished turning---Drilling the

hole---Grinding inner bore---Treaded hole--- Keyway milling---Heat

treatment---Finish turning---Package Packing and

DeliveryAll our ring die mold exportation by wood box packing.FROM

FACTORY TO CLIENTS , REDUCE SPARE PARTS COST FOR ALL FEED

MILLS IN THE WORLD.FAQQ1. How can the die characteristics be

determined?A: This is where experience becomes an important factor.

The selection of a die specification is often the result of a

compromise between the different needs of the many formulas produced

in a production plant and from the specific properties of the actual

plant. The most common mistake is to assume that the die is the

cause of all problems. Pellet quality can depend on many factors

that have nothing to do with the die, the most common being poor

steam-conditioning of the formulas. To overcome these problems,

dies with a high compression index (i.e. large thickness) are

used.Q2. What is your terms of payment?A: T/T 30% as deposit, and

70% before delivery. Below 1000USD order, 100% should be paid as

deposit. We'll show you the photos of the products and packages

before you pay the balance.Q3. What is your terms of delivery?A:

EXW, FOB, CFR, CIF.Q4. How about your delivery time?A: Generally,

it will take 30 to 60 days after receiving your advance payment. If

we have your popular model as our storage, we can deliver within 2

days. The specific delivery time depends on the items and the

quantity of your order.Q5. Can you produce according to the

drawings?A: Yes, we can produce by your technical drawings or your

samples.Q6. Do you test all your goods before delivery?A:

Yes, we have 100% test before deliveryQ7. How do you make our

business long-term and good relationship?A:The experience we have

gained over the years ensures: •high-quality raw

materials including high chrome steels •state of

the art plant and machinery implementing cutting edge

technology •gun drilling and mirror-polishing of

holes •vacuum hardening - heat

treatment •negligible die distortion during heat

treatment •rigorous quality control prior to

delivery /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Ring Die Pellet Mill Design Ring Roller Die as Spare Forging Parts of Pellet Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup