Dongguan Chuanghui Automation Co.,

Ltd. is a branch of Keepro Industry Group, founded in 2009 and

specialized in developing and producing various high quality

automatic feeders, like vibratory bowl feeders, centrifugal

feeders, line feeders, step feeders, and robotic screw fastening

machines, like handheld screw fatening machine, platform XYZ

automatic screw robot and customized automatic screw fastening

system upon our customers' demands. The main applicable

industriesare automotive, home appliances, electronic, automobile,

electrical components, 3C etc.

Based on our strong R&D

ability, advance technology and professional customer service, we

have built a long term cooperative relationship with the worldwide

famous customers, like Honda, Nissan, Emerson, Molex, Volkswagen,

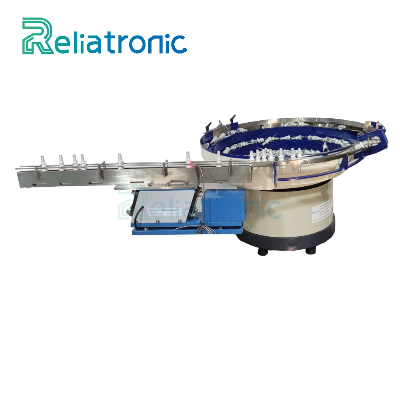

Panasonic, TE, Flex, Mabuchi Motor and so on. Vibratory bowl

feederOur unique patented multi magnet drive units ensure smooth

consistent feed characteristics with minimal vibration to the

assembly machine.Bowls can be made of a range of materials,

including stainless steel, aluminium, polyamide, with different

coatings(polyurethane, habasit, brush, flock, metaline and so on),

selected to suit the application.Sizes range from 120 mm diameter

to 1200mm diameter, Reliatronic represent a complete range of

vibratory bowl feeders available from stock,including drive units,

bowls, bowl centers, control boxes and additional accessories

(stands, base plates, sound covers and sensors). Special

requirements are available upon request.We manufacture tooling to

orientate components, which together with our standard equipment,

provides a system ready to integrate with a customer's further

process machinery, packaging and assembly lines.What is a vibratory

bowl feeder?Vibratory bowl feeders are the most common part feeding

devices used to feed components in Industrial Assembly Automation

Applications. Vibratory feeders are self-contained systems,

comprising of a specially tooled bowl feeder that orients the

components, a vibrating drive unit upon which the bowl feeder is

mounted and a variable-amplitude control box.How does a bowl feeder

work?The bowl feeder, including an out feed accumulation track to

convey parts along and discharge into the assembly machine are

supplied in many shapes and sizes. The drive unit, available in

both electromagnetic and pneumatic drives, vibrates the bowl

feeder, forcing the parts to move up a circular, inclined track.

The track is designed to sort and orient the parts in consistent,

repeatable positions. The track length, width, and depth are

carefully chosen to suit the application and component shape and

size. Special track coatings are applied according to shape size

and material of the parts which aids traction, damage to the

product and lower acoustic levels. A variable speed control box is

used for controlling the vibration of the bowl feeder and stops the

flow of parts to the out feed track via sensors.ComponentsProducts

DescriptionKey BenefitsApplication /* March 10, 2023

17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Automatic Spray Pump Vibratory Bowl Feeder for Filling and Capping Assembly Project

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup