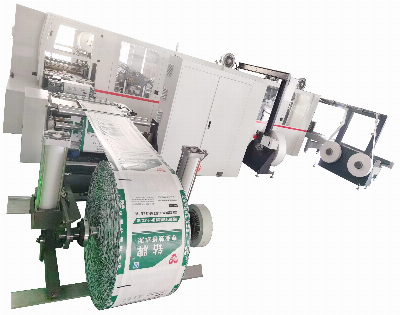

Product Description 6.1 GeneralThe machine adopts Hot Air

Welding Technology and Magnetic Transport Technology, and is for

making the block bottom valve bags from Polypropylene Woven Tubular

Fabric with PP and PE layer coated.Product Parameters 6.2

Technical DataBag size range:Bag width: 350-600 mmBag length:

450-910 mmBottom width: 80-160 mmOpen bottom width: 170-340

mmBottom center distance: 350-750 mmTube cut-off length: 530-1090

mmValve:Flat fabric width: 170-330 mmCut-off length: 80-200

mmBottom cap:Flat fabric width: 75-175 mmCut-off length: 230-480

mm(Bottom width > 160mm is possible only for open-mouth

bags.)Output (Production speed):For bottom width < 140mm: Max.

110 pcs/minFor bottom width > 140mm: Max. 95pcs/min(Depending on

material properties and bag dimensions.)Installed Power:Power

(Excluding air compressor)Power supply: 88Kw, : A.C., 3-phases,

380V, 50Hz, NeutralCompressed air requirements:Pressure: 6

BarCapacity required: 120 m3/hCooling water

requirements:Temperature: Max. 18ºCAmbient air

requirements:Temperature: 16ºC-40ºCRelative humidity: Approx.

60-95%Space requirements:Overall dimension (L×W×H): 14000×7000×2280

mmDetailed Photos /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about PP Square Bottom Valve Cement Bag Making Machines, Block Bottom Cement Bag Sack Machines Ad Star Bag, Automatic Cement Bag Production Line, Square Bottom Bag

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup