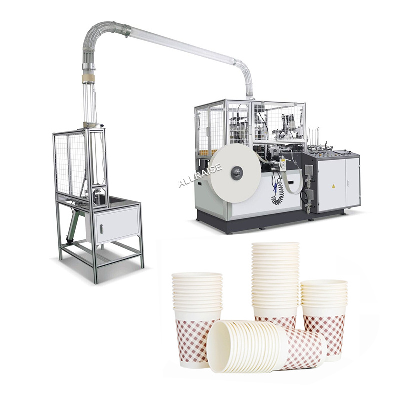

Product DescriptionUltrasonic Automatic Paper Cup Forming Machine

Making machineORZBJ-120 Ultrasonic Automatic Paper Cup Forming

Machine uses a cylindrical indexing cam with only one aluminum

plate to complete the cup making structure, which makes the machine

faster and smaller. It has photoelectric detection, fault alarm,

counting and other functions. Through automatic transmission, paper

feeding, sealing (adhesive cup type), oiling, punching, bottom

turning, heating, knurling, crimping, cup collection and other

continuous processes, it is to improve the production of beverage

cups, tea cups, coffee cups, and advertisements. Ideal equipment

for paper cups and tasting cups, with a production capacity of

70-90 pcs/min. Product Parameters Model OR-RN-ZBJ-120

Cup size 1.5-16oz Material 150-380gsm single PE coated

paper&double coated PE paper;PLA coated paper Speed 70-90

pcs/min Voltage 220V50HZ/380V50HZ or customized Power supply 8KW

Air supply 0.6Mpa (running consumption 0.4Nm3/min) Weight 2500kgs

Dimension 2250*1240*1900mm product features ORZBJ-120 High

Speed Machine to Make Disposable Paper Cup use table style, To

separate mould system from transmit system, the transmission parts

are set inside of machine body which under the table. The

machine are combined with 1.Whole body structure under

automatic spray lubrication system;2.Vertical shaft transmission

system;3.Open cam system ;4.Gear system. All molds are set-up the

table, which are easy for operation.5.Multiple paper feeding. Three

times paper feeding system, multiple mediation, to avoid unevenness

on both sides of the paper cup.6.Slotted wheel-make the machine

inside-connection more tightly, and it is not easy to loosen during

the operation of the machine.7.Single plate bottom punching and cup

route offset the problem of paper jam and flip bottom. Make the

machine more perfect and improve production capacity .8.Automatic

time control of oil lubrication for full machine, avoid the trouble

of manual oil lubricating, make the machinerunning more

stable.9.Open cam running system replace the connecting rod system

to reduce malfunction rate, increase production speed.10.Open cam,

slotted wheel makes the machine running more stable and increase

machine wear-resistant at high speed.11.According to other models.

RN-ZBJ-120 body use square steel, body weight 2500kgs, machine

running more stable under high speed.12.Taiwan brand reducer, NSK

bearing. Standardized production of parts, strong versatility, good

interchangeability, easy to maintenance. product

detail finish product detail FAQ Don't worry your TT

payment,we do make the shipment as T/C,B/L for your reference!Q:

Why don't person reply to me?A: Our person is 24hours on-line. If

nobody reply you , maybe he has other businesses temporarily. So

please leave yourrequirements on e-mail or chat tool, we will reply

you as soon as possible.Q: Can you guarantee your quality?A:Of

course. We are the manufacture factory. More important, we put a

high value on our reputation. Best quality is our principleall the

time. You can be assured on our production completely.Q: How do you

make your price?A: We make the price according to our comprehensive

costing. And our price will lower than the trade company because we

aremanufacture. You will get lower.Machine Details/* March 10, 2023

17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Ultrasonic Automatic Paper Cup Forming Machine Making Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup