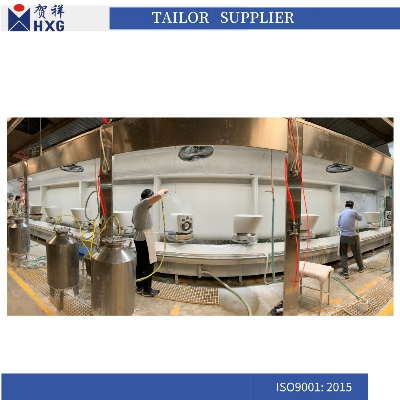

Product DescriptionThe equipment is used for dust removal, glazing

and glaze slurry recovery of sanitary ware of different model. The

glazing line is an automatic circulation line, which is convenient

and quick to glaze, and the holding-bracket is automatically

cleaned, which can achieve the function of recycling, save a lot of

labor and improve work efficiency.Detailed PhotosThe equipment

consists of driving part, transmission part, dust removal and trap

glazing part, glaze slurry circulation part, holding-bracket

cleaning part and manipulator loading and unloading part

(optional). The transmission part comprises a speed reducer, a

driving chain, a transmission chain and an integral frame; Dust

removal and trap glazing part includes dust removal and glazing

cabinet, centrifugal fan, dust blowing pipeline and other main

parts; Glaze circulation system is composed of pneumatic diaphragm

pump and circulation pipeline. Bracket cleaning part is mainly

composed of bracket cleaning cabinet and pipeline pump; There is a

independent manipulators for loading and unloading green

body/glazed piece (optional). Product

ParametersNoItems Contents General parameter 1overall dimensions (L

x W x H) of the overall system:about 38.6m×6m×0.8m × 0.8m.2Total

quantity of unit683working environment temperature:15ºC-40ºCDriving

part1reducer modelCHM-52transmission power3KW3drive chain:cross

drive chain FC400C4Number of driving dials65Speed regulation

modevariable frequency stepless speed change6Conveying speed:15

seconds- 37 seconds/station (2m - 4.2m/min), adjustable in

frequency conversion 3. Transmission part:Transmission part:1model

of circulating chaincross chain C400CDust removal part1model of

sewage pump50GWP20-15-1.52Dust removal type:By water curtainGlazing

1Pneumatic diaphragm pump modelWilton DN802glaze methodwith

pressure spray gun3Glaze circulation mode of glazeBy diaphragm pump

in order to avoid structure polluted by glaze, , all parts touching

glaze are made of stainless steel.Holding bracket cleaning method

1model of sewage pump 50GWP20-15-1.5 The holding bracket

cleaning cabinets are all made of stainless steelFan for dust

exhaust conduct 1centrifugal fan model4-72No12C 2inverter

modelCHE100A-055G/075P-4Working principleIn the driving part, the

holding bracket and green body are moved by a speed reducer and a

driving chain, so that the holding bracket circulates around an

annular track, the holding bracket can be cleaned in a cleaning

cabinet, and then the piece is loaded and unloaded to complete a

glazing cycle.In the glazing dust removal part, glaze slurry is

sprayed onto the surface of the green body with a spray gun, and

some glaze slurry particles float in the cabinet. Under the action

of strong air suction of centrifugal fan, air containing glaze

slurry particles enters the water curtain dust remover. Using the

self-excitation principle, the water curtain is impacted under the

action of airflow, which arouses a large amount of water spray to

form a water curtain, absorbs small particles of glaze slurry, and

eliminates purified air to achieve green environmental

protection.CapacityCapacity calculation, sample by 2 module type

Production is 1-piece toilet working time9Hours per shiftQ'ty of

operator12 Output1200Piece/shift Average output 11Pcs/man/hour

/* March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Carrousel Glazing Producing Line for Sanitary Ware Ceramic Toilet and Wash Basin

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup