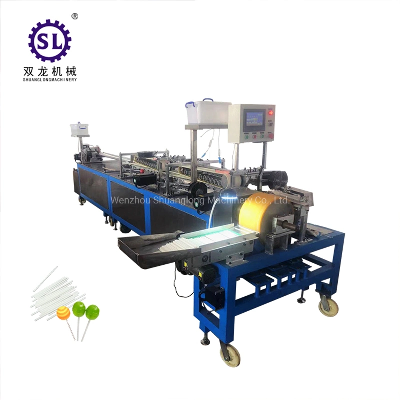

Product Introduction:Working principle of SL-ZB paper stick forming

machine: The paper stick forming machine consists of a paper

feeding mechanism, a looping and twisting mechanism, and a gluing

mechanism. Forming mechanism, and conveyor belt feeding mechanism.

1.paper feeding mechanism:The paper roll fixing mode is

divided into two types: built-in type and outer frame type

according to the diameter of the paper roll. Magnetic powder

tension controller is a device to ensure that the paper has enough

tension to ensure that the paper stick forming belt.2. Paper

cutting machanism:the paper cutting roller will automatically cut

the formed paper stick according to the set length. Note: The

thickness of the paper determines the diameter of the paper stick,

so you must tell the thickness of the paper before ordering. The

thickness of the regular paper: thin axis paper stick: φ1.4-2.0mm,

30-50 grams of paper is used (gram weight per square meter)

Thick-axis paper stick: φ2.0-3.0mm, use 50-70 grams of paper (gram

weight per square meter).3.Paper stick forming mechanism:The rubber

presses the cut shaped paper stick tightly on the shaping template

and twist the paper stick into a predetermined diameter, the formed

paper stick is sent out through the receiving conveyor

belt.4.Gluing mechanism:the glue coating wheel completes the glue

application, and the amount of glue is adjusted and controlled by

the glue motor. Note: glue and making Generally, polyvinyl alcohol

powder is added to water to melt and can be adjusted into paper

stick machine glue. Making method: add one part of polyvinyl

alcohol powder to two parts of water, stir evenly, heat to melt

into syrup, then when using, you can take one part of the melted

glue and add ten parts of water and mix it evenly, because

polyvinyl alcohol is a kind of sugar,so the paper stick made

belongs to the environmental protection paper stick, which can be

used as lollipops and other foods. The end cutting is completed by

the matching machine, and the cutting knife is installed on the

knife holder according to the required size of each manufacturer

and then driven by the rubber wheel,rotate the paper stick and cut

off both ends smoothly.5. Conveyor belt feeding mechanism:the paper

sticks have been cut the end fall on Product Feature:1.Adopt

PLC and touch screen man-machine interface control, with stable

pneumatic speed and overload protection function.2.The

microcomputer automatically adjusts the speed, which can accurately

control the amount of glue required for the paper stick roll and

paste.3.Putting material adopts automatic magnetic powder tension

control to ensure stable paper feeding force.4.Equipped with a

flexible manual deviation correction device, which can quickly

adjust the deviation of the paper strip feeding. Main

ParametersModel numberSL-ZB01SL-ZB02Total

power7KW9KWVoltage380V/50Hz380V/50HzMain motor1.5Kw1.5KwProduction

speed120m/min200m/minPaper stick

diameter1.5mm-2.8mm1.5mm-4.5mmPaper stick length68-150mm(Can be

specified)68-150mm(Can be

specified)Dimension(L*W*H)4000*1500*1550mm6200*1500*1550mmWeight900kg1150kgMagnetic

powder2.5KG2.5KG*2 1. We have more than 15 years

experience;2. We are manufacturer who have been exported more than

15 countries;3. Large production capacity that ensures the shipment

on time;4. Quick responses with full attention5. Sample fee

could be returned after the order has been placed.6. We guarantee

our products quality and pre-sales and after-sales service.1. We

have more than 15 years experience;2. We are manufacturer who have

been exported more than 15 countries;3. Large production capacity

that ensures the shipment on time;4. Quick responses with full

attention5. Sample fee could be returned after the order has been

placed.6. We guarantee our products quality and pre-sales and

after-sales service.Question 1: Where is your factory located? How

can I visit there? Answer: Our factory is located in Wenzhou

City, Zhejiang province, China. The nearest air port is Wenzhou

airport, we can go Wenzhou airport pick you. From SHANGHAI by air

is 40mins, by train is 4hours. From GUANGZHOU by air is 2hours.

Question 2: Do you company provided foreign country machine

installation services?Answer: We have strong service team can

provided all the machines buy from our company foreign country

installation service and engineer training service. But buyer need

provided the ticket, food, hotel cost etc. Question 3: How your

company provided after sales service?Answer: All the machines buy

from our company guarantee is one year (except any human mistake

occurred) , All life time repaire, and 24hours HOT Line. Question

4: What's the payment method?Answer: We accepted T/T, L/C, Western

Union, Moneygram ETC. /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Paper Stick Making Machine for Lollipop Cotton Swab

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup