Laser cutting and technology: Laser cutting is a technique that

uses laser beam to interact with materials to precisely cut,

surface, punch, scribe, etch, nuclear, and micro-machine materials.

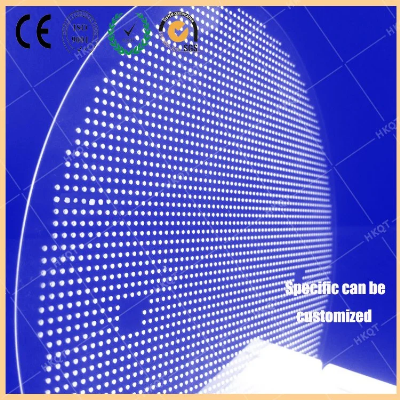

Laser processing features: · High precision, high performance and

high efficiency · Small photoelectricity, concentrated energy, and

less thermal impact · No contact with processed workpieces, no

pollution to the price · Fast punching and smooth hole · The laser

cutting seam is thin, fast and low in heat. · Round and dense group

density. Application range: a) LED chip manufacturing / wafer level

chip package b) touch screen of the navigation device c)

Semiconductor / Lighting d) LCD/MEMS (pressure sensor,

accelerometer...) e) Research / Aviation / Military f) Consumer

Electronics Damage Protection Glass g) Life sciences

(micro-channels, etc.) h) and many other customer-specific

applications Main technical indicators of glass shape

processing | Thickness: >0.1mm | Roundness: ±0.001mm | Collapse:

5mm | Machining accuracy: ±0.01mm | Cutting, punching hours: 5mm /

s | Dimensional tolerance: ±0.003mm | Minimum processing aperture:

Φ0.1mm /* March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about High Precision Laser Micro Hole Processing

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup