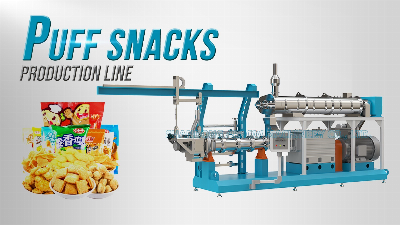

Best quality corn puffs machinery twin screw extruderShandong Arrow

Company is a professional food machinery manufacturer in

Jinan, Shandong Province. Pufffed snacks production line is

one of our hot selling product, it uses rice flour , corn

flour etc as material, It is formed by mold under high

temperature and high pressure environment. It can produce puffed

snacks of different shapes and sizes by changing molds. the

capacity is 100kg/h-5000kg/h(this can be customized as your

inquiry)FLOW CHARTFlour Mixer→Double Screw Extruder→Double Roller

Flavoring Machine→Air Conveyor →Cooling

Conveyor→Oven→PackingMachineArrow Snack Puff Machine production

line is highly automatic and high efficiency. This corn puff snacks

production line adopt twin-screw extrusion technology and are

highly flexible. Corn puff making machine can produce various

uncoated, coated or filled cereal based snacks with a wide variety

of recipes and shapes. Through mixing, extruding, cutting,

drying or baking, seasoning process, delicious product will be

produced. DETAILS OF ARTIFICIAL RICE PRODUCTION

LINENONAMEBRIEF INTRODUCTION1RAW MATERIALRICE FLOUR, CORN FLOUR

ETC 2MACHINE MATERIAL304 STAINLESS STEEL3FLOW CHARTFlour

preparation→Mixing→Cooking&Extruding→Drying→Cooling→Flavoring

→Packing4MACHINERYMIXER→CONVEYOR→EXTRUDER→CONVEYOR→DRYER →

FLAVORING→COOLING CONVEYOR→PACKING MACHINE5PRODUCTDIFFERENT SHAPES

Sample of puffed snacks TWIN SCREW

EXTRUDER(1) Design: Developed by 3D software, analog simulation,

and it has been tested by a computer automatically, in order to

ensure the accuracy of the design requirements.We have a

professional and manufacturing industry to ensure the precision and

coordination of each component of the extruder, while maintaining

stable processing and low noise.(2) Function: Modular function

screw and barrel, humanized menu system, various applications. AYT

double screw extruder for advanced design concepts can meet

different requirements.(4) Materials: Precise food manufacturing

technology and the best alloy metal materials ensure that the wear

of the screw and barrel is minimized, and the service life of the

cable is longer.(5) Application: We produce various kinds of food

extrusion, such as vegetable protein, cereal flakes / breakfast

cereals, pellets, feed / animal feed, etc.(6) After services: We

provide a professional team of engineers to service installation

and commissioning. (1)Siemens China main motor (2) The

screw adopts fully engaged model, designed by 3D design, CNC

machining, smooth surface, high conjunction accuracy, and better

self-cleaning function, changing parts flexibly.(3) The screw and

barrel adopt a combination modular structure, which can be

assembled in any combination to meet different formulas and product

requirements. (4) The screw and barrel are made of special

alloy with high strength and high wear resistance.COMPANY

PROFILE Shandong Arrow Machinery Co., Ltd. is a company

specializing in R&D, production, sales, application promotion

of food engineering projects. As a professional food processing

equipment &whole plant engineering problem solvers in China,

machines served for more than 970 companies, export to 116

countries, more than 20 years engineering team. We aim to create a

great future together with global customers.* More than 15 years

experience* Professional design,fabrication,installation team*

Professional R&D centerOUR SERVICE1. Customized service2.

Quickly delivery3. 24h online technical supporting for free4.

Oversea installation5. High efficiency after sale serviceOUR

CUSTOMER FAQQ: What kinds of products can be made?A: Brewing

type different puffed snacks, such as ball ring, flour etcQ: What's

the delivery time?A: We have some standard machines in stock,

customized machinery usually need 30 working days to finish the

production, testing and packaing.Q: What about the installation

service?A: Depending on the whole line of equipment price list, it

usually takes 2-3 weeks. We will provide you with

installationinstructions, such as start, as well as their operation

machines for quality control, testing of different recipes.Q: What

is the warranty period for using the device?A: 1 year for auger and

cylinder due to modular design, changing the wearing parts will be

OK, unlike a full set of screws, no need to change the whole

set. /* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Best Quality Corn Puffs Machinery Twin Screw Extruder

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup