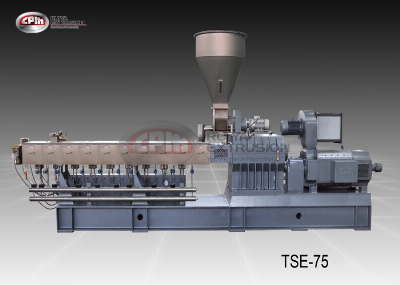

Product DescriptionTSE SERIES ADVANCED FEATURES AT AN ECONOMICAL

PRICETSE-75The TSE series of CPM Ruiya Extrusion is one of the most

commonly used extrusion machines in china. It is the idustry

standard in Asia.TECHNICAL DATAModelD(mm)Central Distance(cm)Max

L/DScrew Speed(rpm)Max power(kw)Torque/shaft(Nm)TSE

7571,06,00726001601210APPLICATION-INDUSTRIES-Adhesives. -Direct

extrusion. -Masterbatch. -Reactive extrusion. -PVC,XLPEandCABLE

compounds MAIN PRINCIPLE AND USE THE TSE series has been

in production for more than 25 years and is the benchmark for

quality among entry level machines.Within this series you can

also obtain the TSE plus.Both series have highly economical prices

and are driven by advanced features.THE TSE Series:THE TSE series

is developed to maintain the same level of throughput,quality and

reliability at a reduced cost.The TSE uses a modern building block

construction consisting of base frame,motor,safety

clutch,gearbox,segmented barrels,and segmented screws.The TSE

typically uses electric heaters and modular cooling with water.At

the most economical solution,all components are sourced from top

Chinese and global suppliers.THE TSE Plus Series:The TSE Plus

allows processors to obtain adcanced performance within the TSE

series.The TSE Plus offers higher output,higher torque,and higher

reliability than the TSE base models.The TSE Plus includes all of

the features of the TSE and the following additions:- European high

torque gearbox with the industry's highest safety factor,low

noise,and significantly longer working life- European high

performance gearbox lubrication system- European safety clutch for

advanced mechanical protection- Frame with increased rigidity and

strength- Barrels and shafts that are interchangeable with the TSE

base models THE ADVANTAGESYOUR BENEFITDesign proven and

refined over 25 years and over 2000 installationsThe benchmark for

quality among entry level machinesThe industry standard in ChinaTSE

Series:- 30 Years approved by customers - With UL & CE

Certification - Heavy duty gear box, much Heavier than

competitors - New compact design oil lubrication unit, using

plate heat exchanger and adding oil temperature and pressure

sensors, for better gearbox cooling - Benchmark in market

Basic ParametersSpeed600rpmTorque density6-8Available

sizes20-177mmTSE Plus Series:- Same Process section as TSE

series machine - European imported Gear Box &Lubrication

system - Safety clutch from UK Basic

ParametersSpeed600rpmTorque density10Available sizes20-177mmMACHINE

DESIGN ENGINEERINGFEATURES Screw geometry based on Chinese

standardsIntegrated torque limiting systemClosed loop barrel

cooling packageProven and reliable gearboxModular barrel

configuration with individual electric heaters,modular cooling by

water,and independent temperature control zonesRobust frame

designVent ports for atmospheric venting Vacuum ports and

vacuum systems for degassing Splined shaft Available with

side feeding barrels and side feeders Available with side feeding

barrels side feedersSelf-wiping segmented screwsAvailable with

maximum screw speeds of 600 RPM User-friendly analog or PLC

control systems Available sizes are 20mm-135mm Company

ProfileLeading supplier of process equipment and systems technology

for the oilseed,animal feed,biofuel,human food and materials

industries.Growth in these markets is driven by population and GDP

growth which increases damands for advanced

proteins,food,materials,and fuel. Founded1883 in san

Francisco,CaliforniaFinancials2022 Projected

Revenues:~$650MMEmployees1260(Americas585,Asia291,Europe384)MarketsOilseed,Animal

Feed,Bioenergy,Human Food,Engineered Materials,and

industrialFaccilities26 facilities comprising of

sales,engineering,manufacturing,and customer service centers in the

Americas,Europe and Asia.Our AdvantagesEquipment and

workshoppackaging&serviceProject Examples4 X 133mm APEX lines

generating a total of 20,000 kg per hour, 5,000 kg/h per machine -

provided to largest ABS producer in the world - very high

reliability requirementsWorld's leading battery separator

manufacturing purchased 8 lines from Ruiya. 23 lines delivered to

the number one producer of TPU in Asia. Turn key line delivered to

world class chemical plant. Modular designed and built compounding

system for US customer. High level specification compounding line

in Shanghai for global leader headquartered in Belgium to produce

unique compounded product (included CPM, feeder supplier and

Automatik). Designed for chemical plant specification including

explosion proof. /* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Cpm Prcocess Solution Twin Screw Extruder/Pelletizing Extruder Tse-75

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup