SMILE AND EASE FOR MAKING MONEY, JUST SWITCH ON OUR

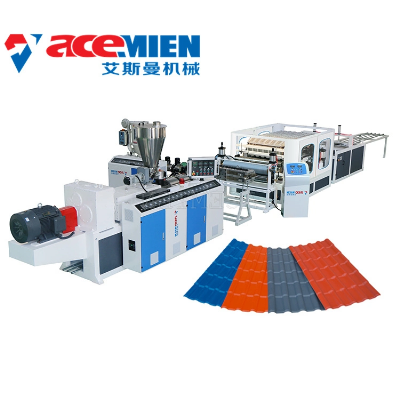

MACHINE1.Profile: PVC Composite Roof Tile

Machinery/Extruder/Equipment/Processing LineThis new PVC composite

roof tile production adopted advanced

multilayer CO-EXTRUSION technology which well combine the

different functions of raw materials(PVC+ASA) so that the tile can

be anti-corrosive, fire retardant, eco-friendly, more

durable, tenacious, easy to install and move, light weight as well

as cost effective in installation (as less steel and less

overlap), as per the efficiency and benefits it provides. It

can save construction cost up to 50%. It has

captured many international certifications for its genius

properties.Apart from its numerous benefits, its salient features

include heat insulation up to 35% (highly

energy efficient) and it can withstand temperature up to 70

degrees Celsius to - 40 degrees Celsius which is

very much suitable for YOUR MARKET.Plastic

Corrugated tile are used for Roofing, can be used

for factories, warehouses, sheds, farmers market, hoardings,

walls, temporary shops, sheds and other very suitable

insulation2.Machine list No.MachineQty.1Screw loader (SJZ

80/156 with push device) 1set2SJZ 80/156 conical

twin-screw extruder (PVC)1set3Vacuum loader and drying

hopper (SJ 50/30)1set4SJ50/30 single screw

extruder (ASA)1set5Extrusion

die 1set6Distributor1set7Embossing roller1set8Forming

machine1set9Cutter machine with dust

collector1set10Stacker1set11Oven (Ridge tile)1set 12Screw

loader1set13Mixer unit1set14Crusher 1set15Pulverizer1setTotal

amount in FOB shanghai port extra cost for PLC Module and

control panel (Brand: ABB AI Schneider Omron

Siemens) 3.Advantages and photos of machineNoMachineTechnical

specifications1SJZ80/156 conical twin-screw extruderExtruder with

double screw feedScrew vacuum with double vacuumFive-zone

heating Joint venture brand instrumentationBimetallic

treatment screw2SJ50/30 single screw co-extruderBimetallic

treatment screw3Extrusion mouldClothes hanger runnerMirror

polishing Cr platingThree dimensional flow simulation software

design4Embossing rollerHard chromium plating on surfaceDesign of

spiral flow passage in rollerMotor separately drive to ensure

consistent speed5Forming machineThe module is a one-time

die-casting moldingModule material LY12 high quality

aluminumAdvanced machining center,one-time clamping of the

moduleFour cylinder lift more stable 6CutterSpecial

positioning device to ensure the cutting accuracyDownside the knife

cutting mode running smoothlyPLC HMI operation7OvenDouble door

double control, upside and downside at the same time operationFlat

open the door, the insulation effect is good and to prevent

burnsAccurate temperature control is in 1 degree4. After-sales

serviceA Provide all the machines for the complete

production according to customer's requirements.

B Provide complete service for factory layout and other

information to help customer to build the factory.

C Provide the raw material to the customer if need.

D Provide good service for machine installation and

training, until the customers can run the machines and make stable

production. E Provide after-sell service for all the

life, except one year quality guarantee. F Provide good

quality, good price and good service to customer, for long-term

cooperation. We are the professional and trustable supplier for

turnkey projects. Let us do win-win business together.

/* March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about One Layer PVC Corrugated Roof Tile Machine/Extruder

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup