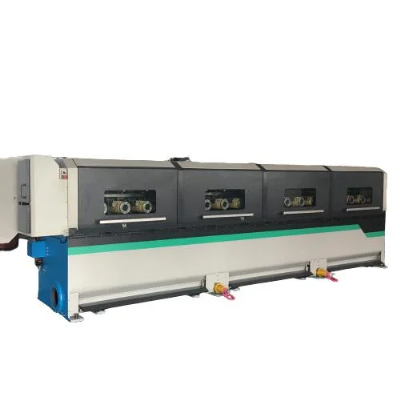

Alpha High Quality Servo Type Micro-slide 32 Wires Continuous

Annealing Drawing MachineApplication:The machine is used for

drawing 32 copper wires from max. Φ1.8mm to min. Φ0.15mm

at same time.The speed of main machine and take-up are all

frequency controlled, and regulated by a PLC with professional

program. Its tension is stable, and it has good synchronization.

The elongation of copper wire is uniform. The speeds are precise at

the states of start and stop, which reduces the length of raw

wire. Product DescriptionNo.ItemPerformance

indexRemark1Wire inlet diameter32*Φ1.8mm 2Wire outlet

diameter32*Φ0.15mm 3Drawing

pass24 4Elongation1.10~1.25 5Max. drawing

speed1500m/min 6Max. annealing speed1500m/min For

Φ0.2 output7Max. annealing current3600ADC8Max. annealing

voltage55VDC9Motors for main machine36~800NmPermanent magnet

synchronous servo motors10Motor for single spooler15kWSiemens

BEIDE11No-load noise≤85db 12Steam

generator3m³/h 13Total power700kVA Detailed

Photos Type: Overhead and vertical type. Max. basket

size:Φ1150mm.There is a alarm of wire break.Features:1.Capstans are

placed on one line, and it is easier to maintain than two lines

arrangement type.2.Drawing capstans is made of 45#

steel through treatments of forging, hardening and tempering,

and coated by Zirconia ceramic ring, to increase

lifetime.3.There is a seal ring on the final die holder to prevent

lubricant linkage.4.Bearing lubricant oil pump is set

externally and driven by a dedicated motor independently connected

with electrical system.No.ItemPerformance

indexRemark1Cooling typeSpray type 2SpeedSize (Φ:

mm)Speed

(m/min)International grade A copper, and the

strength is no more than

280Mpa0.1512000.2015000.2513200.3012000.407200.654803Number of

capstans24 4Number of layers16 5Size of final

CapstanΦ120mm 6Motor60~500NmSelf-produced7Bearing NSK (Japan)8Oil

seal NAK (Taiwan) It has an air pressure sensor. When

air pressure is lower than set value, it will send out a stop

signal. It is safe and reliable.The spooler is full welding

structure. It is compact, good rigidity, and easy for

installation.No.ItemPerformance indexRemark1Suitable wire

diameterΦ0.15~0.8mm 2Spool sizePND630PND500 is

compatible3Max take-up speed25m/swhen bobbin

size≥Φ3504Spooler motors15kW/1470rpmYX2-220M-45Traversing motorServo

motorYASKAWA6Traversing pitch6mm/rInfinitely adjustable7Traverse

max width460mm 8Traversing motor1.5kW 9Clamp

typePneumaticMechanical lock in case of reversing10Brake

wayPneumatic brake 11Meter counting error

ratio≤3‰ 12Take-up no-load noise85db Electrical

control systemThere is a remote monitoring system, which can send

the machine information and alarm to our service technician. Our

service team can prevent the failures and solve some problem

remotely. This system can improve running stability and reduce

maintenance time. No.ItemPerformance

indexRemark1Power380V/50HzThree phases five wires2Motor

driverInvertorsDanfess3PLCS-1500Siemens4Color touch

screen5.6 inSiemens5Relay and contactor

Related products about Alpha High Quality Servo Type Micro-Slide 32 Wires Continuous Annealing Drawing Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup