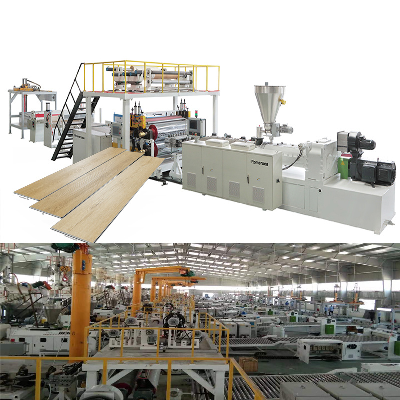

Product DescriptionHIGH SPEED MIXING MACHINEFOR SPC FLOORING

PRODUCTION LINEMixer machine is first step of SPC flooring

production process. Mixer is used to mix raw materials. SPC

flooring raw materials are PVC-SG5, CaCo3, and some other materials

such as stabilizer, PE wax, etc, to mix according to a certain

ratio. Our mix machine has advantages of convenient feeding, dust

free, high production efficiency, low failure rate.

CertificationsSPC Flooring Mixing machine

specification:Romeroca Mixer Machine have different types according

to the volume of hot mixing and cooling mixing. Machine

Type500/1000800/25001000/30001500/6000Hot

Mixing500L800L1000L1500LCool

Mixing1000L2500L3000L6000LSpecification of High Speed Mixing

Machine RFS-MM1000/3000.No.1Specification of 1000/3000

mixer 1Mixer Vacuum FeederSUS304 , 2MM, 200L, transition silo

800L Feeding Fan 11KW MC-90 dust

collector 24 φ150×600 filter

elements2Hot Mixing Total

Volume 1000L Effective

Volume 800L Motor

Power 160KW, Siemens

Standard Mixing Time 6~8

Min/Barrel Materials SUS304,8MM

for Barrel /10MM for bottom Leaf

for Mixing SUS304,

20MM Material for

mixing 400~450KG/time Capacity >2000KG/H 3 Cooing

Mixing Total

Volume 3000L Effective

Volume 2000L Motor

Power 30 KW Mixing

Time 6~10 Min/Barrel Leaf

for

Mixing SUS304 Capacity >2000KG/H 4 Transition

Silo Materials SUS304,

2MM Motor 1.1KW 5 Screw

Feeder Materials φ114mm,

SUS,

2MM Leaf SUS Motors 3+1.1KW Capacity 3000kg/H

Detailed PhotosFeatures of Romeroca SPC Flooring Mixing

Machine--Consists of a high-speed hot mixer and a cooling

mixer.--Famous brand electrical appliances to ensure stable machine

operation.--Adopt screw feeding, with automatic feeding time,

overload protection.--It is widely used for mixing various resins

such as PVC, CaCo3,Stabilizer etc.--In the hot mixer, the

temperature rises rapidly to meet the requirements of the material

mixing process.--This machine occupies a small area, low energy

consumption, easy to control, time saving and efficiency.--The

material from the hot mixer will be automatically loaded into the

cooling mixer. And the cool water recycle systemin the cooling

mixer to meet the requirements of the production process.OUR

ELECTRICAL PARTNERSOUR CERTIFICATESOVERSEAS PROJECT CASESFULL

WORKING PROCESS OF SPC FLOORING After Sales ServiceOUR

SERVICES & AFTER SALES 1) 12-months warranty on all Romeroca

machine (excluding wear parts).2) 36-months tracking service,

prompt response within 24 hours.3) Providing factory production

process and machine layout design.4) Providing technical guidance,

training and support.5) Providing timely supply support for spare

parts.6) Other support from raw materials, machines to finished

products. Our Advantages About us/*

March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Convenient Feeding High Production Efficiency Spc Flooring Production Line Mixing Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup