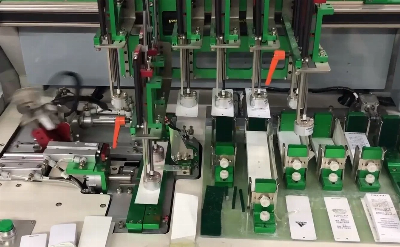

Our Factory is Trustworthy!!!Industrial Automatic Double Pieces

Hangtag Stringing/Folding/Collecting

Machine (SP-F108) Product

Details: Advantages:Automatically suck trademarks, automatic

multi-layer folding, automatic rope threading, and automatic

material collection at one time Application Case:It is widely used

in the production of hang tags such as clothing, bags, shoes and

hats. Specification:Minimum label size 25×50mmAir pressure

0.5Mpa,1.8L/min Maximum label size 70×360mmWeight100KgVoltageSingle

phase220V Dimensions 1300×950×1780mmPower4Kw

More Main Products:About us:About us

Modern fashion industry has entered a customized and intensive

development and the manufacture of the future fashion industry will

be a technology-intensive and highly intelligent model ,the trend

posing series of challenges against traditional manufacturing

model. Supreme, ' customer-focused '

,focusing on customer needs , provides overall exclusive solutions

for individual needs by supporting technological innovation.

Special industrial sewing machine ,automatic sewing

units and customized products: with strong R&D advantages

,through mechanic design ,motion control ,sound, light,visual

control ,WIFI ,RFID and other technologies,it achieved

breakthroughs in the technological innovation of sewing

machinery,using forward-looking vision and leading mind,which in

return provides customers with high-quality and efficient

products. Intelligent factory field : build an

elite team of 100 people for the whole process of the smart

factory, bringing together a group of professionals with deep

industry background and rich practical experience. Based on

self-developed CPS/PLM/QMS/WMS/APS/MES,core information system that

perfectly integrated the IOT intelligent sewing equipment that in

tegrate intelligent control technology.intelligent perception

technology ,imagine recognition and sewing material motion control

technology , so that materials and products have dynamic storage,

perception, and communication capabilities. Through the real-time

transmission and sharing of data, visualized process control and

omni-directional system supervision are realized, so as to achieve

intelligent selfmanagement and self- organization of equipment, and

selfmonitoring and self-decision-making of flexible production.

Equipped with an advanced intelligent logistics and warehousing

system, it builds a highly energy-efficient, green and

environmentally friendly humanized chemical factory, and continues

to create maximum value for customers.Packaging & shipping:FAQ:

Related products about Industrial Automatic Double Pieces Hangtag Stringing/Folding/Collecting Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup