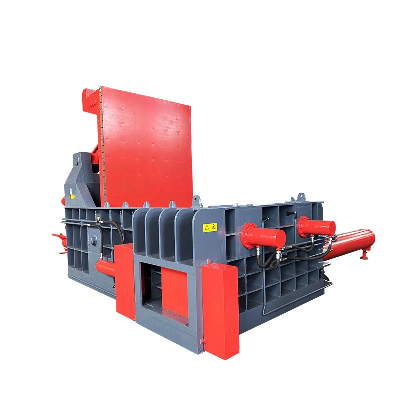

The metal packing and pressing hydraulic press can extrude various

metal wastes (scrap, shavings, scrap steel, scrap aluminum, scrap

copper, scrap stainless steel, scrap cars, etc.) into qualified

furnace materials of various shapes such as Rectangular cuboid,

octagon, cylinder, etc., which can not only reduce the

transportation and smelting costs, but also increase the furnace

feeding speed. This series of balers are mainly used in steel

mills, recycling industries, as well as non-ferrous and Ferrous

smelting industries. They are stable, safe and reliable. They are

ideal equipment for new and old customers to become rich.Metal chip

pressing machine can directly cold press powdered cast iron chips,

steel chips, copper chips, aluminum chips, mineral powder, iron

drums, etc. into cakes for storage, transportation, and furnace

recycling and reuse. After being pressed into blocks, it is put

into the furnace for recycling with extremely low loss. The entire

production process does not require heating, additives, or other

processes, and is directly cold pressed into shape, ensuring that

the original material remains unchanged while forming. For example,

cast iron filings are used instead of cast pig iron after forming.

For castings made of special materials, recycling has greater

significance.Users can customize packaging specifications and sizes

as needed to maximize coordination with transportation or

storage,It is a good equipment for improving labor efficiency,

reducing labor intensity, saving manpower, and reducing

transportation costs.Working principle of the metal briquetting

machine series:Place the materials that need to be packaged in the

material box of the molding machine, use hydraulic oil cylinders to

work and compress the packaged materials into shapes, ultimately

forming various types of packaging blocks.Advantages of using a

metal briquetting machine to press blocks:1. The transportation of

metal materials after pressing is convenient, which can effectively

reduce transportation costs and increase transportation

efficiency. 2. After pressing, the metal is easily crushed for

secondary processing.3. Block metal materials are easier to store

compared to metals, which can save a lot of warehouse space.4. The

pressed metal greatly facilitates its use and reprocessing.Product

application:The metal briquetting machine is mainly suitable for

environmental protection enterprises, recycling companies, steel

mills, electronic and electrical enterprises, aluminum profile

manufacturing enterprises, aluminum foil manufacturing enterprises,

etc. Used for packaging: scrap steel, construction steel bars,

household appliance shells, refrigerator iron shells, computer

mainframe iron shells, aluminum profiles, waste non-ferrous metal

products, etc.FAQQ:Are you a trading company or a manufacturing

factory?A:We are a factory.Q:What is your delivery time?A:If the

goods are in stock, it usually takes 7-10 days.If the goods are out

of stock, it will take 15 to 30 days, calculated by quantity.Q:What

is your payment method?A:30% of the total price should be paid in

T/T as the down payment; 70% of the remaining payment should be

paid in T/T before delivery.Q:Do you provide technical

guidance?A:Yes, we will provide you with professional advice on the

selection of models and the operation of equipment. /* March

10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Hydraulic Press Machine for Scrap Iron, Aluminum, Copper, and Metal Scrap

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup