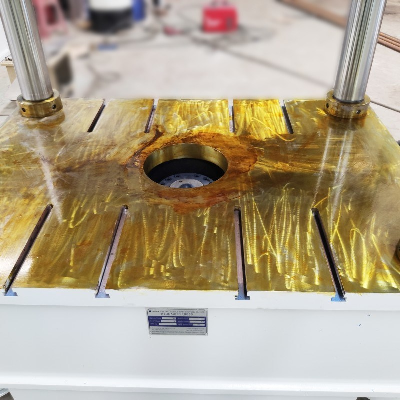

HARSLE 315T High Speed Pressing Four-Column Hydraulic Stainless

Steel Punching power PressProuduct Specification Y32-Series

Four-Column Three-Girder Hydraulic press machine Machine Features

1. Computer-optimized structure design, three beams and four-pillar

structure, simple, economical, and practical. 2. Hydraulic control

system Adopt cartridge valve integrated system, reliable, long

life, and small hydraulic impact, reducing the link pipe and leak

points. 3. Independent electrical controlling system.working

reliable, easy maintain. 4. Adopt the button centralized control,

with adjustment for manual and semi-automatic operation. 5. Through

operator panel to choose from, can be achieved given away two

constant pressure forming process, and have features such as

security during rolling. 6. Slider working pressure load and slow

down quickly work into the travel range can be adjusted according

to process requirements. A hydraulic press is a machine that uses a

hydraulic cylinder to generate a compressive force. This force is

typically used to shape or form metal, compress powder, or crush

objects. The basic components of a hydraulic press include:

Hydraulic Cylinder: This is the primary component that generates

force. It consists of a piston inside a cylinder filled with

hydraulic fluid. When pressure is applied to the fluid, it acts on

the piston, creating a force that can be transmitted to the object

being pressed. Hydraulic Pump: The pump is responsible for

generating the hydraulic pressure required to move the piston. It

draws hydraulic fluid from a reservoir and pressurizes it before

sending it to the hydraulic cylinder. Control Valves: Valves are

used to control the flow of hydraulic fluid, enabling precise

control over the movement of the hydraulic press. Different valves

can be used to adjust the speed, force, and direction of the press.

Frame: The frame provides the structural support for the hydraulic

press. It must be robust enough to withstand the forces generated

during the pressing operation. Worktable or Bed: This is the

surface on which the material or object to be pressed is placed. It

can be flat or have specific features depending on the intended

application. The operation of a hydraulic press involves filling

the hydraulic system with fluid and applying pressure to the

hydraulic cylinder. As the piston moves, it exerts a force on the

object placed on the worktable, achieving tasks such as forming,

shaping, or compressing materials. Hydraulic presses are widely

used in various industries, including metal forming, rubber

molding, plastic molding, and powder compaction. They are valued

for their ability to exert high amounts of force evenly and

consistently, making them suitable for a range of manufacturing

processes. /* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about 315t High Speed Four-Column Hydraulic Steel Press Supplier for Sale

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup