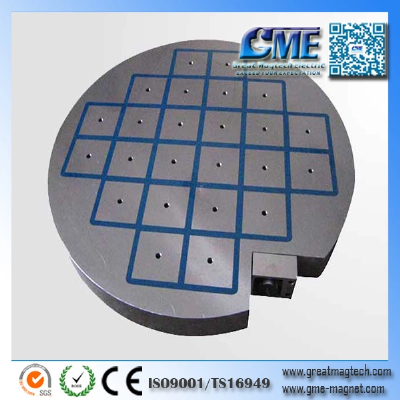

Magnetic chucks include several types such as electromagnetic

chucks, permanent magnetic chucks and permanent electromagnetic

chucks, each having particular functional features.In the

machining industry, it has been known since the beginning of the

20th century to apply magnets to holding workpieces. In

particular, recent technological development has expanded

applications of magnetic chucks from grinding machines only to

heavy duty cutting processes by machining centers, lathes, milling

machines, etc. Today the applications have further been

expanded to include metallic moldmachining and electric discharge

machining. Thus, the magnetic chucks that meet these high

precision machining requirements play a very important role in

many machining fields.In addition to magnetic chucks, GME

offers chucks designed for nonmagnetic materials to respond to

requirements in grinding of various materials. We believe you

will find products in this brochure that meet your diversified

needs. Overview and features of

chucks: ElectromagneticChuck1. Very efficient since workpieces

can be loaded/unloaded just by switching operation.2.

Automatization in machining process is realizable by interlocking

the chuck with the machine tool.3. Attraction is electrically

controllable.4. Easy to make larger type of chuck.Water-Cooling

TypeElectromagneticChuck1. Constructed to reduce heat generated

during power on by water cooling.2.Used for high precision

operations and exhibits features of electromagnetic chucks

effectively.3.Most suitable for dry grinding.(Heat from workpieces

is absorbed also)PermanentElectromagneticChuck1. Very effcient

since workpieces can be loaded/unloaded just by switching

operation.2. Energy-saving, since electric power is used only

mome-tarily for loading/unloading workpieces.3. High accuracy due

to no change with time passage.4. Never any trouble due to

suspension of powder supply.PermanentMagnetic Chuck1. Energy-saving

type, requiring no power source. No fear of power failure and can

hold workpieces for a long time.2.No heat generated and thus no

thermal distotion due to temperature rise.3. Uniform magnetic force

irrespective of chuck sizes.Sine Bar Chuck1. Magnetic chuck

equipped with sine bar for high precision grinding and

inspection.2. Precisely finished to overall accuracy of 0.05mm or

better.3. Various types are available from electromagnetic,

water-cooling electromagnetic, permanet magnetic and permanent

electromagnetic chucks.Vacuum Chuck1. Holds workpieces by action of

atmospheric pressure2.Vacuum chucks nonmagnetic materials.Promote

System1. Secures workpieces to a special chuck using workpiece

fixinig material.2. Secures nonmagnetic materials. Standards

of electromagnetic

chuck: Length or

diameter of face plateup to 300Above 300,up to 600Above 600,up to

900Above 900Surface roughness:6.3SMounting face: Not

convexFlatness0.010.0150.020.025Parallelism0.020.030.040.05Holding

powerThe holding power on the chuck face plate must be 98.1N(10

kgf)or over in average and 49N(5kgf)or over in the weakest

area.Withstand voltageDielectric breakdown between the charged part

and the body is not allowed.(1500VAC,1min)Insulation resistanceThe

insulation resistance must be 5ΩM or over.(Measured with 500 V

insulation resistance meter)Temperature riseThe temperature rise on

the chuck work face must be below 15ºC.(Powered on for 3

hours)Water resistanceWhen a chuck is immersed in water, it must

not allow water to enter the inside or its insulation performance

must not drop.Note: The standards of the holding power and

temperature rise vary according to models. Types of

chucks by applications:MachiningApplicationMachineHeavy duty

cuttingMaterial roughcuttingMachining centerMilling

machineLatheTurning machineGeneral cuttingMaterial cuttingGeneral

finishingLight duty cuttingFinishing (Straightening)Heavy duty

grindingMaterial grindingRotary grinderSurface grinderBelt

grinderCylindrical grinderMold grinderGeneral grindingGeneral

finishingFinishing(Straightening)Precision grindingPrecision

finishingElectricdischarge machiningMold machiningElectric

dischargemachineNonmetallicmachining(Weak magnetism)Grinding

cuttingMachines in general

Related products about Supper Radial Pole Chuck Diameter

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup