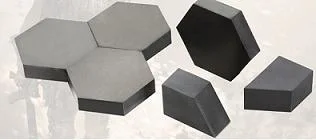

Product DetailsThe pressureless sintered silicon carbide (SSiC)

ceramic products are made of ultra-fine silicon carbide powder and

sintered at high temperature. The silicon carbide content is more

than 98% and without free silicon, yielding the product density

more than or equal to 3.10g/cm3. What's more, our products

have a great deal of technical advantages, such as high mechanical

strength, high hardness, wear resistance, high temperature

resistance, strong acid and alkali corrosion resistance, oxidation

resistance, thermal shock resistance, good thermal conductivity,

extreme cold and heat resistance and high temperature creep

resistance. As a result, the products are widely used in many

hign-tech fields, such as milita*y industry, aerospace, nuclear

power, metal smelting, high-temperature furnace, lithium-ion

battery production, powder metallurgy, ceramic chemical machinery,

ultra-fine grinding, paper-making, medicine and so on.Hot Pressed

B4C

CeramicItemsUnitValueValueComposition%B4CB4C+SiCDensityg/cm3≥2.50≥2.80Porosity%≤0.1%≤0.1%Flexwral

StrengthMPa≥330≥350Fracture

ToughnessMPa.m1/2≥3.0≥3.8HardnessKg/mm2≥3100≥3000Elastic

modulusGPa≥380≥400Compressive strengthMPa≥2000≥1800Sound

velocitym/s// 3rd-Party Test ReportProduct PackageWe

use foam pads and cartons or wooden boxes for packaging to ensure

that the packaging is stable and firm, and avoid damage to the

product during transportation. Production ProcessCompany

ProfileOur company is committed to research, development,

production and marketing of high-performance pressureless sintered

silicon carbide ceramic products. It adopts a complete set of

domestic advanced production lines, including dry pressure molding,

normal pressure grouting, pressure grouting and extrusion molding.

It has applied for six national patents, one utility model and five

invention patents. It mainly produces pressureless sintered silicon

carbide ceramic products, including pressureless sintered silicon

carbide ceramic rollers, chemical heat exchange tubes, square

beams, process furnace tubes, grinding media, thermocouple

protection tubes, thermal radiation tubes, combustion nozzles,

grinding barrels, multi curved breast plates, helmets,

wear-resistant pipes, wear-resistant elbows, saggers, crucibles,

plates, pump shells and other precision parts.WorkshopOur

Advantages• Competitive Price• Many Specs Stock Goods•

6000 tons / Month Stable Output• 40+ Stable Partners fom All Over

the World• 11 Years Experience in Producing and Exporting•

Mature R&D & QC Teams to Ensure Good & Stable QualityCustomer

Reception

Customers from

Turkey visited our factory and negotiated business. FAQ

Q1: Are you trading company or manufacturer?A: We

are manufacturer.Q2: Are samples free or not?A: Sample in

stock can be free of charge. Only shipping needs to be

paid by your side. Q3. Can you customize according to my

drawing or requirement?A: Yes, we can customize, and we

offer OEM and ODM service.Q4. Do you test all your goods before

delivery?A: We have laboratories to test the chemical and physical

properties of our SiC. We will repeatedly test during

production and before shipping to ensure that the product meets the

appointed standards. Looking forward to receiving your

inquiry.Please feel free to ask me if you have any questions. Thank

you ^^/* March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about B4c Boron Carbide Ceramic Plate Tile

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup