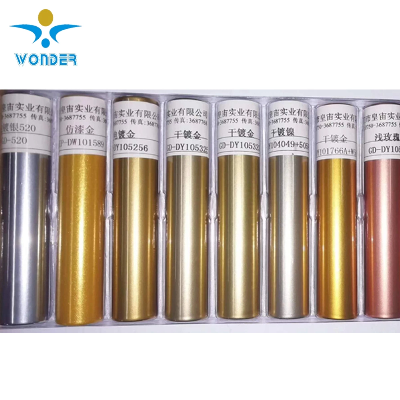

Chrome Metallic Silver Gold Color Chemical Powder Coating for

Aluminum with ISO9001Product DescriptionPowder coatings

are mixed with a certain proportion of the resin, fillers,

curing agents and other additives, and then prepared by hot

extrusion, crushed and sieved. The products are stable at

room temperature storage, and then baking heat melted and

solidified to form a smooth and bright permanent coating to achieve

the purpose of decoration and anti-corrosion. Product

DetailsTypeEpoxy-Polyester Indoor

Chrome TypeColorChrome Surface FinishsmoothGloss

level 100-120%Particle SizeAverage 32-42μmSpecific

Gravity1.2-1.7g per cubic meterCoverage8-10 square meters per Kg at

50-90 μm film thicknessfilm thickness60-80μmApplication

RecommendationApplication Voltage60-90 KVGun to Component

Distance15-20CMCuring Temperature200 degree / 10

minselectric current25-30MASpray RoomClear, no other powder

coating Air pressure AppropriatePowder coated Film Mechanical

PropertiesAdhesionCross-cut(3mm),no loss of adhesionImpact

ResistanceDirect impact 50kg/cmPencil Hardness2HCupping Test6mm

MandrelBending Test5mmPowder Coated Film Chemical ResistanceSalt

Spray Test5% NaCl Solution for 500 hours - No changeAcid

Resistance5% HCL for 48 hours dip test - No changeAlkali

Resistance5% NaOH for 48 hours dip test - No changePowder

Coating Advantage RatioSpray ratio is 90%Square 1KG of powder

coating can spray 8-10 square meterAdhesive forcePowder

Coating adhesive force is stronger 8-10 yearsColorPowder

Coating is not easy to fade in 5-8 yearsStorage StabilityStore

in ventilated, dry, clean room, temperature

Related products about Chrome Metallic Silver Gold Color Chemical Powder Coating for Aluminum with ISO9001 10%off

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup