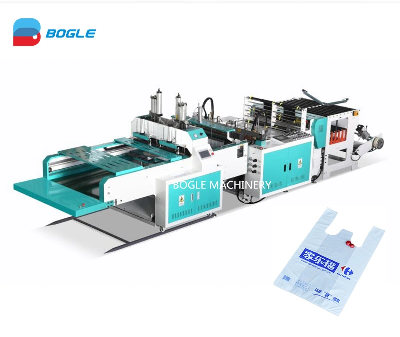

Product Feature:This machine is specializing in manufacturing

plastic T-shirt bag with HDPE LDPE film material, suitable for

making both printed bags and non-printed bags.Double

lanes working same time.12mm thickness iron plate structure, strong

and solid frame decrease the vibration when working at top speed,

ensure sealing cutting punching accuracy.Pneumatic loading material

rolls.2.5KG Magnetic powder brake on unwind station. The

material feeding control system adopts analog control, 0.75KW EURA

Brand simulation automatic synchronous feeding.1.5KW main motor

drove the machine, with 1.5KW Eura brand frequency inverter

controlling.Double 3.7KW Inovance brand servo motors controlling

material feeding.SICK brand photocell tracking eye, for making

printed bags accurately, machine stop automatically if label

lost.Heat sealing heat cutting technology, the cutting blade with

transformer heating, copper sealing bar, middle heating tube and

both sides of the heating plate double heating.The double lanes

material's feeding, sealing, cutting and punching and transporting

is finished in one process.PLC controlling and CL-2016B touch

screen operation, auto counter, quantity setting, both Chinese and

English 2 languages.With digital

temperature controllers to adjust the temperature of the 2

sealing bar, heat bar and hot pin.With 2 PCs

static eliminators to get rid of statics on film surface for better cutting.The

punching device is controlled by PLC and Touch

Screen. Air tank installed on both cutting and punching part to enhance air supply.With

inverter

controlling on punching machine, to ensure steady operationTechnical

Parameters:ModelBG-500*2Bag Making Width (Max)450mm*2Bag Making

Length (Max)650mmBag Making Speed250-350pcs/min*2linesSingle Layer

Thickness 0.008-0.02mmMain Motor 1.5KWTotal Power16KWMachine Weight

2.2TonDimension (L*W*H)7m*1.8m*1.9mMachine Photos:Details of

Machine:Unwinder:12mm thickness iron plate Independent

unwinder with pneumatic loaderIndependent material storage

rackLay-on-roll device for tension controlling Auto shut down when

the material used outHeat weld device for connecting the material

when change rolls Web Guider:Ultrasonic EPC, ensure the

material feed accurately Bag Sealing Cutting Part:12mm

thickness steel plate Double servo motor feeding

materialDouble Panasonic brand material blocking sensors

Bag Sealing Cutting Part:12mm thickness steel

plate Double Panasonic brand material blocking sensorsPLC and

Touch Screen conttoller with English and Chinese

Sealing and Cutting Part:High quality copper bar with middle and

side heater Alloy steel cutting blade with transformer

heatingDouble Panasonic brand material blocking sensor Air

blowing function for cooling the sealing line Touch Screen

Controller:Both Chinese and English languageAuto counter, auto

alarm or stop when the bags' number reach the setting

quantity Length of bag and speed adjustable Punching

Part:Double Taiwan brand cylinder PLC controlling and touch

screen operation Conveyor Belt:Plastic bag folded

function Transport the finished plastic bags

Sample Bags Photos: Other Related Machines:Film Blowing

Machine

Printing Machine

Bottom Seal Bag Making MachineOur

Factory:Our Customer Feedback:Certificate:Package &

Loading:FAQ:1.:Are you manufacturer or trading company ?We are

manufacture, specializing in plastic package machinery filed more

than 15 years, we have own export sale team.2. Where is your

factory?Our factory is located in Ruian,Zhejiang Province, China,

about 1hour far away from Shanghai or Guangzhou, after you arrive

Wenzhou Airport or Ruian Railway Station, we will drive and pick

you up there, welcome to visit our factory.3 What's the deliery

time?Generally, the delivery time is about 30-40 days, if you need

machine urgently, we also could shorten the delivery time.4.:What's

the quality warranty period?one year quality guarantee, within the

period, freely provide replacement at the buyer delivery cost, life

long after sale service and technical support, 5:What's the

package method?The machine will be cleaned and packed with stretch

plastic film to avoid dust. 6.Does your factory provide

installation and trainning service?We could appoint engineer go to

the buyer's factory to do installation and trainning at the buyer's

cost.7:What are your terms of payment?We accept T/T and L/C.

/* March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about High Speed Automatic Heat Sealing Heat Cutting HDPE Nylon Polythene Vest Handle Poly Supermarket Grocery Store PE Shopping T-Shirt Plastic Bag Making Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup