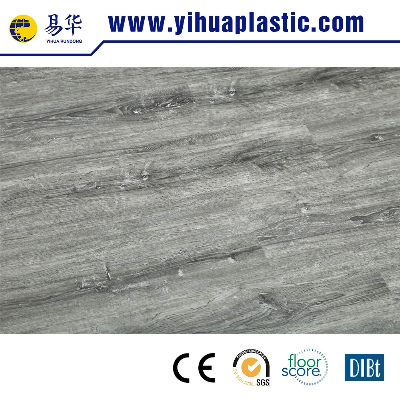

Product DescriptionLuxury Vinyl Tile, PVC FlooringProduct: LVT

(Loose Lay, Dry Back, LVT Click), SPC Click , WPC ClickColor: Wood

Design/Stone DesignPackage: PalletizedMOQ : 1000m²/ColorPayment

Terms: 30% T/T deposit. 70% T/T against copy of B/L or LC at

sightLead Time: 30~45 days(1) LVT Dry BackSize:

6''x36'', 9''x48'', 12''x24'', 18''x18'', etc.Thickness: 2mm,

2.5mm, 3mm Wearlayer: 0.1mm~0.7mm(2) LVT

Loose Lay(Anti-slip Backing, Sticky Backing)

Size: 18''x36'', 9''x48'', 18''x18'', etc.

Thickness: 4mm, 5mm Wearlayer:

0.3mm~0.7mm(3) LVT Click Size:

180x1210mm,220x1210mm,304.8x609.6mm, etc.

Thickness: 4mm, 4.5mm, 5mm Wearlayer:

0.3mm~0.5mm Available for length

1.5m/1.8m (4) SPC Click

Size: 172x1210mm, 218x1210mm, 300x600mm, etc.

Thickness: 4mm, 4.5mm, 5mm Wearlayer:

0.15mm~0.5mm Available for length

1.5m/1.8m Specially for Residential

Use (5) WPC Click Size:

180x1210mm, 220x1210mm etc. Thickness: 5.5mm,

6mm, 6.5mm, 7mm Wearlayer:

0.3mm~0.5mm Available for length

1.5m/1.8mDetailed Photos CertificationsCE, ASTM, Floorscore,

ISO9001, BSCI......Packaging & ShippingInstallation

InstructionsLaying instructions- CLICK

SYSTEM General:Then execution of

floor-covering work is construction work within the terms of the

German Construction Contract Procedures (VOB). The VOB Part C DIN

18365 "Flooring Work" thus provides the basis for the execution of

flooring work and the laying of flooring.Before choosing the

appropriate floor covering it is always necessary to know the

on-site type of use and existing sub-floor in order to select the

right and proper flooring. Only in this way can added value and

value maintenance throughout the planned lifetime of the floor

covering be guaranteed.Sub-floor:The sub-floor must be even, clean,

sufficiently dry, free of dust and cracks, and sufficiently

load-bearing. It is always necessary to prime mineral sub-floors so

that no dust is present on the existing sub-floor. Before carrying

out the flooring work an evaluation of the sub-floor in accordance

with DIN 18365 "Flooring Work" is necessary. As design flooring are

vapor-proof coverings, residual moisture in the sub-floor is

particularly significant. It is to be demonstrated that appropriate

measurements have been taken. With existing underfloor heating

there should be an appropriate heating protocol to ensure the

sub-floor is ready for the installation of the

flooring.Installation:•Checking the floor coveringOur CLICK-design

flooring undergo a strict quality control procedure that guarantees

high-quality standards. If, contrary to all expectations, material

problems should be identified on site, there are to be notified

before cutting to size and laying. Claims for obvious defects (e.g.

Color variations, differences in thickness, surface defects,

insufficient accuracy of fit etc.) cannot be accepted after

laying.If a number of packages of design flooring are being used

the contents should be checked for batch-to-batch variation before

cutting and laying. When ordering it is imperative that reference

be made the need for a consistent color-matched delivery with no

batch variation.•Interior climatic conditionsThe floor covering

must be adapt to the room temperature before laying. This requires

at least 24 hours acclimation. For installation the room air

temperature must not be less than 18ºC and temperature of the

sub-floor not less than 15ºC. The relative humidity should not

exceed 75%. With underfloor heating floor temperatures of between

18ºC and 22ºC are o be observed.In the winter months the underfloor

heating should be kept at a low temperature for at least 72 hours

before the floor covering is laid, during laying, and for at least

hours after laying (see surface temperatures). Rapid or distinct

changes in temperature can cause gaps or warping in the

flooring.These climatic conditions are to be maintained for at

least 48 hours before laying the flooring, during installation, and

also for at least 72 hours after the flooring has been completed.

Larger changes in room temperature are to be undertaken gradually

in accordance with the usual room climate conditions.•Laying the

floor coveringPriming is always recommended on mineral sub-floor in

order to bind dust and particle matter and thus to prevent noise

being generated when the flooring is in use..Before laying the

CLICK-design flooring the room is to be measured and assessed in

terms of laying direction and starting point.We recommend the use

of our Click-Underlay, which not only has a noise-mitigating and

heat-insulating effect but also compensates for slight sub-floor

irregularities and impurities without adverse consequences.The use

of Click-Underlay is imperative with the following sub-floors:

parquet, laminate, ceramic tiles (with joints of max. 5mm width and

2mm depth), PVC-flooring and flat stone floors. The "sticky"

surface significantly reduces vertical movement to the sub-floor.

The underlay is used tra

Related products about Wood Design Spc WPC PVC Floor Tile Vinyl Flooring

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup