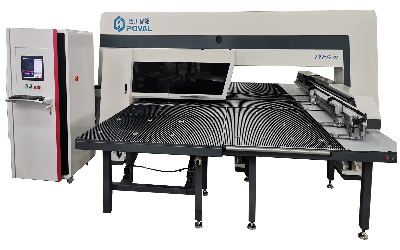

CNC Press Machine/CNC Punching machine/CNC Perforating machineCNC

Turret Punching Machine is mechatronics automation equipment, it's

widely used in the chassis cabinets processing, air

conditioners, refrigerators, range hood, instruments and meters,

electric control cabinet panels, battery plate, building decorative

materials, auto parts, silencing plate, lamps, kitchen equipment,

and other sheet metal processing

industries.SpecificationUnitAMD-SE3510Transmission mode/Electric

servoPunch forceKN300Power ratingKW35Processing sheet sizemm5000*1500

with

repositioningProcessing sheet thicknessmm≤6Max. Punch diametermmØ88.9Sheet moving speedm/min80Punching frequency

(nibbling)hpm1700Hole accuracymm±0.1Number of stations in turret No.16/24/32Turret rotational

speedrpm30Controlled axisNo.4Rotating locationNo.2Air pressureMpa≥0.8Outline Dimensionmm4490*5300*2110Machine WeightT13Feature:1.

Adopts Fanuc/Rexroth 4 axis CNC special system and match up

digital AC servo motor to make it fast and reliable;2. Fuselage

is open type Steel welding, the whole pass by tempering

treatment to own good rigid and hardly deformation;3. With the

second positioning function, can achieve without dead zone

processing;4. The transmission system use the international brand

with high precision, big guide ball screw, linear guide rail are

high precision and good performance;5. Main pneumatic components,

electric components, hydraulic components and transmission adopt

perfectly;6. Use AMADA standards casting integrated thick turret

mold disc and standards internationally general thick

molds.Notice:According to your requirements, the most suitable

machines will be designed for your workpieces, please

indicate the following details.1. Please tell us your metal

sheet material.2. The steel sheet dimension, including length,

width and thickness.3. The information of your punched hole

diameter.4. It's my pleasure if you can send some photos or

drawings of your products for us reference.Based on these

details information, the detailed technical proposals will be sent

to you for reference.Japan FANUC or Germany REXROTH control

system;AMADA Standard 80mm Ductile Iron Thick Turret Disc;Taiwan

TBI/HIWIN Ball Screw & Linear Guide;International electrical

components;Secondary positioning system & auto-index.FAQ: 1.

Production time: 30-40 days according to different

type. 2. Installation and commissioning time: About

10 days. 3. Installation and commissioning issue: We

will send 1 technicians to help with machine installation and

commissioning, customer pays for their tickets, hotel and

food. 4. Warranty time: 1 year after installation.5.

Payment term: 30% as prepayment, balance 70% before delivery

or L/C at sight. 6. We supply full English

documents: Including general installation drawings, pit design

drawings, manual book, electric wiring diagram, electric manual

book and maintenance book, etc. WHY CHOOSE US?1. China famous

brand & top quality supplier.2. 17 years manufacturer

experience, 10 years export experience.3. Professional technical &

service team.4. Machine exported more than 80 countries over the

world.5. All the machine parts are international brand, quality

guaranteed.6. Customize & flexible products and service.Welcome to

visit our factory in Qingdao!

Related products about Monthly Deals Blinds CNC Turret Punch Press Machine/CNC Punching Machine/CNC Perforating Machine for Stainless Steel Plate

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup