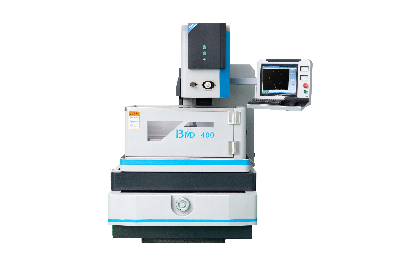

Product Description1) Automatic parameter generating

system.2) Inverter control wire running .3) Standard DRO and

Z axis motorized drive up and down.4) Import linear guide,ball

screw .5) Automatic center lubrication system. (Not manual

).6) Window XP System with Auto-CAD software control

System.7) Automatic wire tension system.8) Standard 6-12degree

taper cutting system. 30-60 degree precision large taper angle

option. 9) Gemstone guide wheel is durable and operation

stable. 10) LED Inside light .11) High pressure water tank

with paper filter .The advantages: The

Integrated CNC EDM Wire Cutting Machine

: 1, Guide screw: Adopt Taiwan ball screw inward guide

rail to ensure the accuracy retention of the machine for more than

10years. 2, Z axis: adopt X and Y guide rail of

the same grade, with high rigidity. Adopt high grade photoelectric

switch for reversing, so as to improve the cutting stability of the

machine tool. 3, Wire parts: ball screw, linear guide,

ensuring vertical accuracy. 4, Servo control of Japan

Panasonic servo motor, effectively ensuring accurate

position. 5, The consistency of product: the operator can only

input the processing requirements is okay. After years of practical

processing experience, we have developed a professional

database to solve the consistency of the

products. Product

Parameters Model BMD-400ABMD-400BBMD-500ABMD-500BBMD-630ABMD-630BWorktable

size(mm)635*415635*415785*500785*500900*600900*630Worktable(mm)400*320400*320500*400500*400630*500630*500Max

Workpiece Thichness (mm)adjustable 280280280280280280Max

workpiece weight(kg)400400500500800800Max

Productivity(mm²/min)≥220mm2/min≥250mm2/min≥220mm2/min≥250mm2/min≥220mm2/min≥250mm2/minBest

surface

roughness(Ra)Ra≤1.0μmRa≤0.8μmRa≤1.0μmRa≤0.8μmRa≤1.0μmRa≤0.8μmWrie

diameter(mm)0.1-0.25mmTaper angle 6°/80mm-12°/80mmPrecision

large taper angle 30°-60°(DK-Z

series)90mm-100mmAccuracy(mm)≤±0.005mm≤±0.004mm≤±0.005mm≤±0.004mm≤±0.005mm≤±0.004mmPower

supply380V/50HZ 220V/50HZ Company

ProfileSUZHOU BAOMADE ELECTROMECHANICAL CO, LTD is located in

Suzhou City, national High-tech Development Zone. The company is

a professional manufacturer for electrical

discharging equipment. It is mainly engaged in the research of

electrical discharging machine and special technology and relative

equipment. The medium speed wire cut EDM machine is featured

in multi-cutting function, high efficiency, excellent finish

surface, the effect is close to that of brass wire

cutting. The high speed small hole drilling machine, fast

speed EDM wire cutting and medium speed wire

cutting machines are exported to the United States,

Italy, India, Pakistan, Singapore, Egypt and other countries of the

world. We can provide DK7725--DK77100, BMD400A--BMD800A and

other series of products with machining efficiency up to 250mm²/min

and smoothness Ra

Related products about High Speed Sreel CNC Wire Cutting Bmd-400

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup