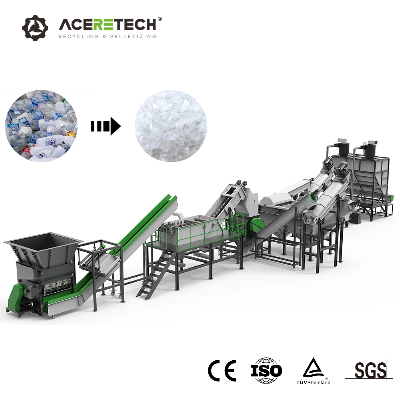

Aws-Pet Quality Assurance Plastic Waste Pet Bottles Washing

Recycling Line with Omron Temperature ControllersProduct

DescriptionAs we all know, the recycling of PET bottles is the most

important part of plastic recycling today, and ACERETECH has also

focused on the research of PET recycling for many years.Usually we

have the following steps to deal with complete PET bottles,

sorting → crushing → washing → drying.PET waste bottles are

dirty and must undergo strict washing before granulation to remove

oil, dust and other sundries. In addition, waste PET bottles are

often accompanied by accessories such as bottle caps, labels, and

bottom brackets, because they are usually made of made of PP/PE and

other materials, they are incompatible with PET. Therefore, in the

recycling and pelletizing process of waste PET bottles, these

accessories must be sorted out separately.Product ParametersDevice

parametersSizeCapacityMotor PowerEquipment

footprintAWS-PET101000kg/h220KW250m 2AWS-PET202000kg/h260KW350m

2AWS-PET303000kg/h380KW500m 2AWS-PET404000kg/h500KW700m 2Unit

energy consumptionContentAverage energy consumption per ton of

bottleElectricity70-90KWWater1-1.5TCompressed air0.5-1m3Steam

(optional)250-400KGDetergent (optional)4-8KGBottle quality

referenceDescriptionAA(ppm)A(ppm)PVC content≤25≤100PE/PP/colored

bottle/metal/other≤75≤100Total impurity≤100≤200Product

Details Company ProfileFAQYOU ARE WELCOME TO OUR FACTORY AT

ANY TIME* ACERETECH is original manufacturer.* If you interested in

our products and we can fulfill your request , you may pay a visit

to ACERETECH Factory.* The meaning of visiting supplier, since

seeing is believing, ACERETECH Machinery with own manufacture and

developed& research team, we can send you engineers and make sure

the high efficiency after-sales service.SEE ACERETECH MACHINE HOW

TO ENSURE THE QUALITY* In order to ensure the accuracy of each

part, we are equipped with a variety of professional processing

equipment and we have accumulated professional processing methods

over the past years.* Each component before assembly needs

strict control by inspecting personnel.* Each assembly is in charge

by a master who has working experience for more than 15

years* After all the equipment are completed, we will connect

all the machines and run the full production line for at least 12

hours to ensure the stable running in customers' factoryTHE

AFTER-SALE SERVICE OF ACERETECH MACHINERY* After finishing the

production, we will debug the production line, take photos, videos

and send them to customers via mail or instant tools.* After the

commissioning, we will package the equipment by the standard export

package for shipment.* According to the customer's request, we can

arrange our engineers to customers' factories to do the

installation and training.* Engineers, sales managers, and

after-sales service managers will form an after-sales team, online

and offline, to follow the customers' project.

Related products about Quality Assurance Waste Plastic Pet Bottles Washing Recycling Line with Drying Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup